U.S Custom orthotics

orthotics process

Here is an inside look at the orthotic process and manufacturing process. All foot orthotics and orthotic inserts are made in our foot orthotic lab in NYC by certified Pedorthists led by Jeffry Rich

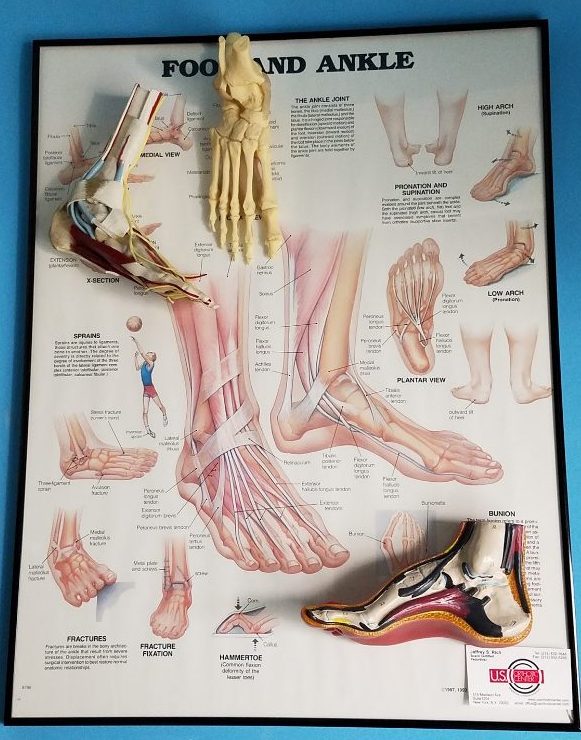

Understanding Your Foot and Symptoms

Once examines the Pedortist will explain to you using charts and foot models, his findings, and recommendations. Also, which shoes and orthotics combination would be best for your condition. U.S Orthotic Center will suggest you orthotic models that would work best to treat your foot condition and outline a course of action to follow. Orthotics are a work in progress and we will work with you throughout the orthotic process.

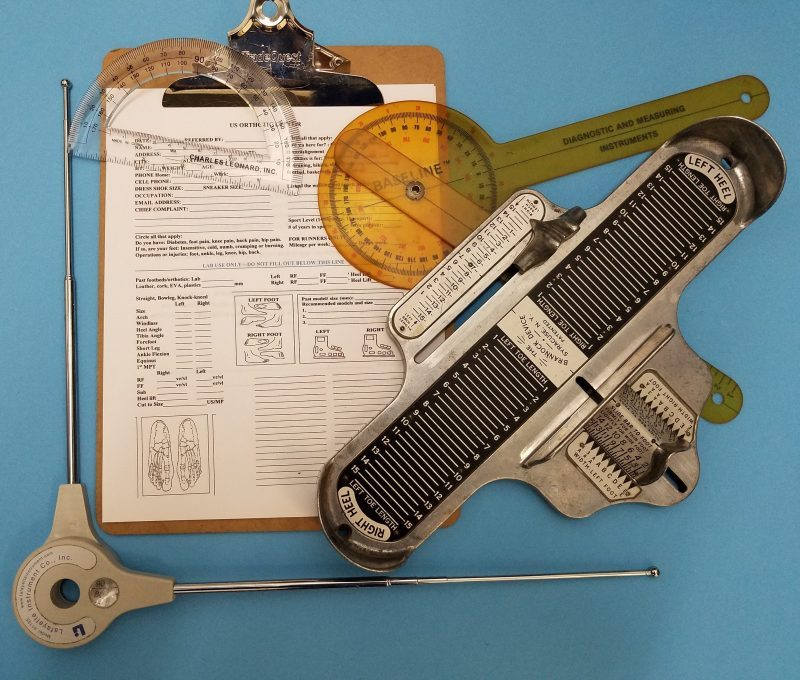

First Encounter –“The Consultation” The Crucial part of the Orthotic Process

Our board-certified foot specialist begins by reviewing any prescriptions and medical reports you bring to the appointment. We will ask you to point out any pain or discomfort in your foot, ankle, knee, hip, or back, and the pedorthist will ask you a series of questions regarding the pain or discomfort. During the orthotic process consultation, we evaluate your feet by taking ten different precise measurements of your toes, feet, ankles, and lower legs to determine your foot balance and health. The measurements allow us to precisely design your orthotic inserts.

Grinding the Orthotic/Adding Corrections

Grinding is a part of the Orthotic Process. This is where art meets science! Using a band saw and round wheel grinder, each custom orthotic is trimmed to remove excess bulk and is ground to a smooth flat surface. Then, wedges and/or cushioned layers are added to the orthotic to help balance your foot and alleviate your pain.

Grinding the Orthotic/Adding Corrections

Grinding is a part of the Orthotic Process. This is where art meets science! Using a band saw and round wheel grinder, each custom orthotic is trimmed to remove excess bulk and is ground to a smooth flat surface. Then, wedges and/or cushioned layers are added to the orthotic to help balance your foot and alleviate your pain.

Shoe Fitting Orthotic

All orthotics are made on-premises. When you pick up your newly created orthotics, they will be trimmed down and shaped to fit your footwear. The orthotics, depending on the model, will fit into a variety of dresses or athletic shoes. Orthotics are a work in progress. If they don’t fit into a particular shoe or your pain has not been resolved, you can make an appointment for an adjustment. At U.S Orthotic Center, your orthotics come with 3 complementary adjustments to be done within the first 3 months. Adjustments in most cases are done during your appointment. Your pain-free comfort is our goal!